Advanced Compressor Design

Innovative Design and In-House Manufacturing for Superior Quality

At our company, we take pride in designing and manufacturing our air screw compressors entirely in-house. With a state-of-the-art CNC workshop spanning 500 m², we have the unique capability to precisely control the quality of critical components. This ensures that every compressor meets the highest standards of reliability and performance, making our products truly one of a kind in the region.

We understand that every industry has its challenges. That’s why we offer fully customizable solutions, tailoring our compressors to perform seamlessly in even the most demanding working environments. Whether it’s extreme temperatures, high-duty cycles, or other challenging conditions, our compressors are designed to keep your operations running smoothly.

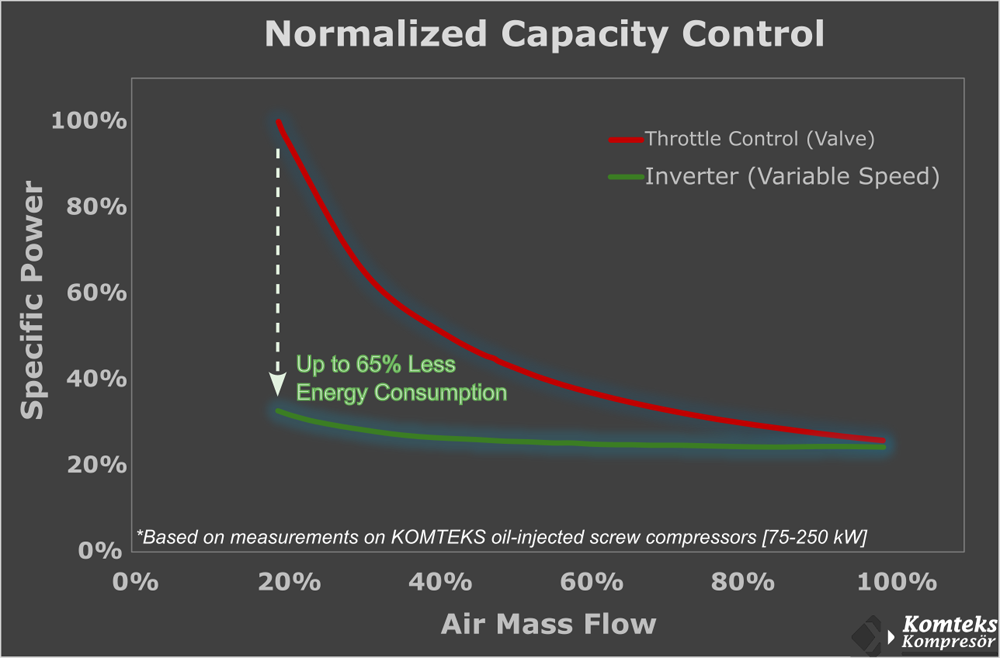

Variable Speed Technology for Maximum Efficiency

As strong advocates of variable speed technology, we have chosen to move away from proportional throttling after conducting comprehensive research with our partners. Our high-quality, inverter-equipped screw compressors are designed to provide the most efficient working conditions across a wide range of air demands.

In addition to optimizing performance, we offer a reliable contingency plan with star-delta switching from the inverter. This ensures that even in the rare case of an inverter failure, your air supply remains uninterrupted.

To further enhance efficiency, our electric motors are equipped with temperature sensors, and the integrated inverter and control system continuously process sensory data to achieve maximum operational efficiency. This intelligent monitoring ensures optimal performance and energy savings at all times, even under varying demands.

Thermal Management Designed for Extreme Conditions

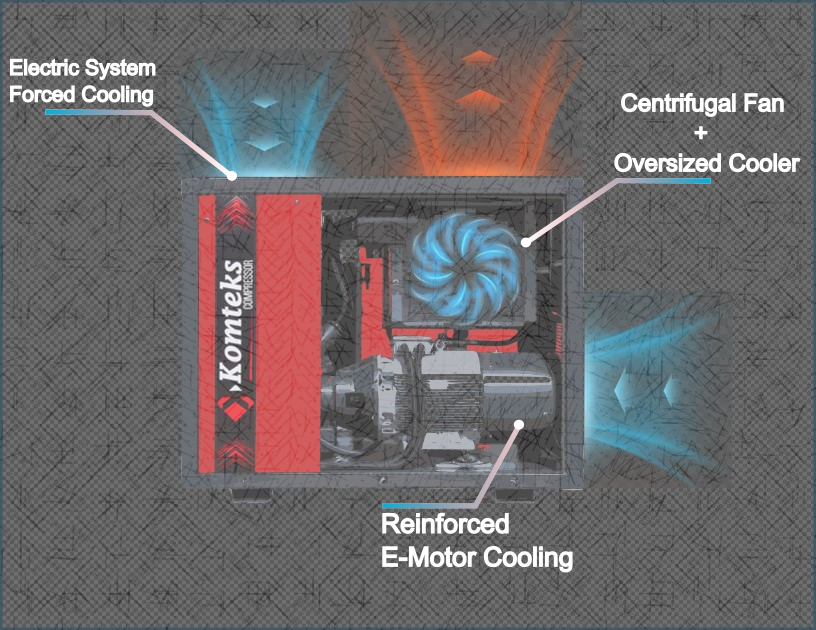

With over 30 years of experience, we have continuously optimized our compressors to perform reliably in the hottest and most challenging environments. We understand that air compressors often face regional weather challenges, such as high temperatures and humidity, which can impact performance and durability. Based on decades of customer feedback, we have implemented several advanced thermal management features:

Oversized Heat Exchanger: Ensures effective cooling even in extreme heat.

Low-Pressure Centrifugal Fans: Depending on the compressor size, we use up to three fans to provide efficient cooling and maintain consistent airflow.

High-Speed Forced Electric Motor Fan:Improves motor efficiency and prevents overheating for continuous, reliable operation.

Extra Forced Fan Cooling for Electrical Systems:Guarantees that no heat-related failures occur by keeping critical components within safe operating temperatures. These innovations ensure that our compressors deliver superior performance and reliability, even under the harshest conditions.